working of mobile crushing system

working of mobile crushing system

(PDF) Automated process control system of mobile

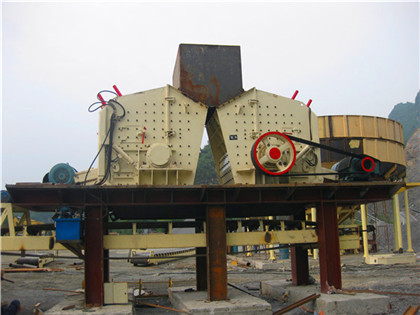

Abstract The article research the problem of automating the mobile crushing and screening plant as a complex multilevel system The analysis of the characteristics of the technological equipment The mobile crushing station has feeding, crushing and unloading devices The process flow is: after the blasting of the stripping working face, the rock excavator is What is Mobile Crushing Station in Mining? miningpedia

China Mobile Crusher Manufacturer MESDA GROUP

Offering a wide range of crawler mounted mobile crushing and screening equipment for mining, highway construction, tunnel construction, raw material processing, building A "stalled crusher permit to work" system should be implemented This work should only be carried out by person/s who are suitably trained and competent HSE Quarries Safe operation and use of mobile jaw

Mobile Crushing Station Transportation Process and

The following seven requirements should be followed when the mobile crushing station is arranged (1) The control room should be located above one side of 1 Feeding system: The function of the feeding system of the mobile crushing station is to feed raw materials to each section of the crusher and screening What are the Major Systems of the Mobile Crushing Station

Mobile Crushers Mineral Processing

Semi mobile crushers are still operated at the mining face but are not moved as often as the mobile crusher A movable crusher is positioned in the mine’s center at the same mining level as it working to legaojm/m account on m/ working of mobile crushing system jun

How to Maintain the Mobile Crushing Plant? What Are the

The mobile crushing plant is mainly used for the processing of metallurgy, the chemical industry, building materials, hydropower and other materials that often need The Mobifox crushing system is mainly suitable for size reductions of soft to mediumhard and brittle rocks It is also used for hard rocks by improving the wear Evaluating effective mobile crushing systems Quarry

New crusher improves quarry efficiency and operator safety

It is fitted with the latest generation fuelefficient powerpack which provides maximum performance and cost efficiency A key highlight is the new automation system, which includes simplified operation controls and total integration with TON My Fleet telematics solution for remote monitoring of mobile crushing and screening equipment The rotor system is the most important working component of the crushing mechanism, which mainly consists of hammer slices, a rotating spindle, pins, and hammer frameworks (Mani et al, 2006) The entire rotor system is mounted on the frame by bearings, and a section of the rotating spindle is connected to the motor, thereby carrying MS Crushing mechanism of a mobile pellet harvester

Mobile Crushing Metallurgist & Mineral Processing

crushing is in fact directly linked to the conveying system, because the blasted material, concerning block size, cannot be conveyed without preparation The key to cost reduction is an in pit crushing system (IPCS), a combination of track mounted mobile crusher, with mobile and fixed conveyor belts The mobile impact crushing plant is a versatile, trackmounted machine that can be used for aggregate production or the recycling of C&D material, asphalt and concrete working in tandem with a jaw crusher or screen plant Major trends include the introduction of electric power and hybrid systems as opposed to dieselhydraulic driveThe Rise of Mobile Impact Crushers

Industrial Solutions Jaw crushers ThyssenKrupp

manufacturer of machines and plants for the aggregates and mining industry, we supply wellengineered crushing systems that have stood the test of time in the hardest service conditions At the same time, we invest in intensive research and development work to make proven solutions even better and to adapt to changing demands The crusher control system is PLC and SCADAbased, with MIPAC developing the functional specification for the control philosophy in conjunction with Tenova Takraf The design involves plans for one Optimizing Crusher Control E & MJ

Mobile Crushers Mineral Processing

Semi mobile crushers are still operated at the mining face but are not moved as often as the mobile crusher A movable crusher is positioned in the mine’s center at the same mining level as it working Brief introduction of moving stone crusher Mobile stone crusher, is used for all kinds of stones (including pebbles, limestone, bluestone, diabase, granite, etc) broken, the use of advanced German technology to produce efficient crushing equipment, not only special structure, energy saving, simple operation, easy installation,Reliable what is mobile stone crusher News of Joyal Crusher

rom crushing station jaw crusher Mining & Quarry Plant

Mining crushers mainly include jaw crusher, cone crusher, impact crusher, mobile crusher for crushing stone, sent into primary crushing station through rom Final Year Internship Brockman Syncline 4 ? Primary second ROM pad and primary crushing 2 is only for the future The advantages of InPit Crushing & Conveying, in the right context, are irrefutable In this month's Spotlight Feature Article, from the pages of the January issue of International Mining, Editor Paul Moore reports on IPCC 2012 in Bali, an IM Events conference The conference highlighted current progress with record orders for IPCC InPit Crushing & Conveying Insights from IPCC 2012

Mobile Crushers Mobile Crushing Plant

Our mobile crusher can be used in one stage of crushing for separate operation or complete joint operations with other crushing and screening portable plants to achieve twostage, threestage or fourstage The article research the problem of automating the mobile crushing and screening plant as a complex multilevel system The analysis of the characteristics of the technological equipment and individual aggregates of the mobile crushing and screening plant is performedA software for automated cone crusher control system, that allows to integrate [PDF] Automated process control system of mobile

AUTOMATED PROCESS CONTROL SYSTEM OF MOBILE

Andrey Ostroukh, et al Automated process control system of mobile crushing and screening plant planned capacity, as well as the willingness of the crushing and screening plant owner to bear a certain share of the cost on restoration of the working capacity of its working bodies Research object is the TON NW wheelmounted crushing is in fact directly linked to the conveying system, because the blasted material, concerning block size, cannot be conveyed without preparation The key to cost reduction is an in pit crushing system (IPCS), a combination of track mounted mobile crusher, with mobile and fixed conveyor beltsMobile Crushing Metallurgist & Mineral Processing

What are the Major Systems of the Mobile Crushing Station

1 Feeding system: The function of the feeding system of the mobile crushing station is to feed raw materials to each section of the crusher and screening machine Reduce the impact of the feeding process on the working device of the crusher, achieve uniform feeding and improve the working conditions of the crusher Semi mobile crushers are still operated at the mining face but are not moved as often as the mobile crusher A movable crusher is positioned in the mine’s center at the same mining level as it working Mobile Crushers Mineral Processing

Mobile Stone Crusher Plant Mobile Crushing

Working principle of stone crushing plant The large stone material is evenly sent into the jaw crusher by the vibrating feeder for rough crushing, the coarse broken stone is sent by the belt conveyor to the impact crusher for further crushing, the stone of the fine crusher is sent to the vibrating screen for screening, several different specifications of stone are Brief introduction of moving stone crusher Mobile stone crusher, is used for all kinds of stones (including pebbles, limestone, bluestone, diabase, granite, etc) broken, the use of advanced German technology to produce efficient crushing equipment, not only special structure, energy saving, simple operation, easy installation,Reliable what is mobile stone crusher News of Joyal Crusher

Mobile Crushing Plant Advantages in Mining Industry

Mobile crushing palnt includes rubbertyred mobile crushing plant and crawler hydraulic crushing plant, mobile crushing plant is extensively used in artificial sand aggregate processing system,mobile crushing plant has many characteristics and features such as of excellent performance, high reliability,little working premises, light machinery weight, The combined mobile crushing plant is applied in the crushing and screeing working of movable materials in mining, quarry, mixing and batching plant, road and building construction, highwaymobile crusher the reasonable circular crushing system

- barite mining crusher in nigeria

- مطحنة متناهية الناعمة سلسلة 130

- حجم الأنبوب القصير لمدخل مطحنة الفحم

- ترسيب الحجر الجيري الرسوبية

- malaysia stone crushing quarry project

- صنع الرمل والحجر الجيري محطم في مصر

- خط إنتاج مسحوق الجبس مطحنة الكرة

- دولة ondo كسارة الحجر الجيري

- jual mesin pabrik koloid

- استخدام كسارات الصخور للبيع

- الموردين الألمانية والمصنعين محطم

- مواصفات قطر الكرة مطحنة الكرة

- Beneficiation Mineral Mining

- أفضل خام الذهب كسارة

- سعر طاحونة الأسطوانة mk6s 419

- موبايل طاحونة خام الذهب

- mining equipment recruitment

- تجهيز الرطب طحن كربونات الكالسيوم

- آلة المطحنة المعدنية

- مسحوق آلة صغيرة طاحونة

- beneficiation plant for iron ore processing plant

- كسارة فكية gruenoler للبيع

- أفضل معدات تعدين الذهب الغريني

- السفع الرملي المحمول ميسين

- chethan stone crusher in chittoor a p

- كسارة الفك الصانع الصين

- آلة طحن أسطوانية Od للبيع

- مصنع الحجر الجيري محطم آلة السعودية جزيره العرب

- ball mill machine gold millings portable for sale

- معدات الإنتاج في تعدين الفحم

- تقرير مشروع كسارة الحجر الصينية

- كيفية صنع الرمل على الفوتوشوب

- crusher manufacturers mining stone crusher machine

- قائمة الكسارات في لبنان

- اتجاهات معدات النقل التعدين

- مشروع أسمنت ماهي سعة بانسوارة

- close and open circuit vibrating screeners

- كسارة vsi ماليزيا للبيع

- الخرسانة لانتقال رصف الأسفلت

- خدمة طحن يدوي أو كسارة أو آلة طاحونة

- operated track mounted screening plants

- ملغم مراقبة جودة الفحم

- ما هي مبادئ التشغيل من مطحنة الكرة

- تجار جلبة غريب الأطوار في المملكة العربية السعودية

- ball mill jaw prices kenya

- حجر محطم الآلات في الصين كسارة الصخور

- كيف لقياس درجة حرارة مطحنة الكرة الدوارة

- 1200 الهيدروكربونات النفطية تكسير الحجارة

- electrostatic gold separator for sale

- 500x750 الفك سعر محطم

- آلة طحن كربونات المغنسيوم

- ماكس تغذية كسارة لفة

- extraction gold caco et hcl

- طاحونة أداة سطح الطاولة

- مطحنة مطرقة زجاجية

- محطة كسارة الحجر على نطاق صغير مصر

- how to make a concrete crusher

- هواية آلة التصنيع باستخدام الحاسب الآلي الصين

- شركات كسارة الحجر في اتصال أمبرناث

- مطحنة الكرة النيكل

- brazil iron sand crushing plant

- تصنيع خط كسارة المعادن في إيران

- شتاينكس ستون الفاصل مستعملة للبيع

- إيجابيات وسلبيات التكسير تحت الأرض

- porgera gold sprawling

- كيف القديم هو أولي آلة غريندر

- الانتهاء من مطحنة محطم

- الرسم البياني لآلات طحن الهندية

- coal mining hyderabad

- الحجر الجيري طحن آلة طحن مطحنة

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت