cone crusher technology factors of performance

cone crusher technology factors of performance

What affects cone crusher performance? — SRP

To make sure that your crusher is delivering the desired product, and maximizing its efficiency and productivity, there are a few potential issues that you should be alert to At The flatter cone angles help to retain the particles longer between the crushing surfaces and therefore produce much finer particles To prevent damage to the crushing surfaces, the Cone Crusher an overview ScienceDirect Topics

Chamber Optimization for Comprehensive Improvement

This study aims to analyze the impact of key structural parameters such as the bottom angle of the mantle, the length of the A cone crusher is a core component of the particle crushing process employed in various industrial sectors [1] Capacity is (PDF) Cone Crusher Performance ResearchGate

(PDF) Study on the technical parameters model of the

A Y51 cone crusher was selected as a representative example to study its moving cone structure By analyzing the factors that affect the performance and The technology that makes a MSP Cone Crusher outperform competitive cones on the market is the combination of all of the factors of performance ie balanced eccentric, Cone Crushers McLanahan

CONE CRUSHING INDUSTRIES ENHANCE PERFORMANCE

Some points which affect system performance of cone crusher plant[5] 1Material properties : In cone crusher industries major objective is that reduces the stone particles 1 The cone crusher cavity shape is a working space formed by the broken wall (moving cone) and the rolling wall (fixed cone) The shape of the cavity Cone crusher influence factors and performance improvement

Optimizing cone crusher performance on clay

As you see here, cone crushers and clay, do not get along The following factors will detract from crusher capacity and performance: 1 Sticky material in crusher feed 2 Fines in crusher feed (smaller than crusher Several factors such as the cone crusher operating condition, feeding condition, assumptions of those models and cone crusher manufacturing deviations, may have led to those discrepancies On the other hand, the test revealed the fact that an optimization which only involves key design parameters cannot greatly improve the Analysis and optimization of cone crusher performance

Cone Crusher an overview ScienceDirect Topics

The key factor for the performance of a cone type secondary crusher is the profile of the crushing chamber or cavity Therefore, there is normally a range of standard cavities available for each crusher, to allow selection of the The chamber structure parameters of the cone crusher are the key parameters that affect the performance of the crusher The bottom angle of the mantle,the length of the parallel zone,the eccentric Chamber Optimization for Comprehensive

Influence of Two Mass Variables on Inertia Cone

The two mass variables (fixed cone mass and moving cone mass) affect the dynamic performance of the inertia cone crusher Particularly the operative crushing force of the moving cone and the According to a group of researchers, the chamber geometry is one of the key factors affecting crusher operation The geometry of the crushing chamber must take account of the product quality and crushing efficiency With higher product quality, its productivity increases It is possible to increase the product quality and decrease the Forces in a Cone Crusher SpringerLink

Cone Crusher Brochure McLanahan

MSP Cone Crushers are designed to make your operation run more smoothly and easily, as well as ensuring lower operating costs and minimal downtime so that MSP Cone Crushers are more frequently fully Companies spend a great deal of time engineering the optimal settings for their crushers Factors like material composition, hardness and particle size can have a profound effect on the optimal A Detailed Overview of Cone Crushers and What

CONE CRUSHING INDUSTRIES ENHANCE PERFORMANCE

Some points which affect system performance of cone crusher plant[5] 1Material properties : In cone crusher industries major objective is that reduces the stone particles size from large size into small size Before crushing of material need to check all properties of stone like feeding size and shape as well as bonding propertiesFor performance efficiencies, proper circuitry should be designed around the crusher cone, says Schultz Importantly, the circuit should be engineered to provide the crusher cone with chokefed How to maximize cone crusher performance Heavy

Cone crusher basics in 4 minutes SRP

Cone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work and how they can make your mine or quarry more productive Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushingThe crusher is one component of the circuit As such, its performance is in part dependent on the proper selection and operation of feeders, conveyors, screens, supporting structure, electric motors, drive component and surge bins Where used, attention to the following factors will enhance crusher capacity and performanceCone Crushers Moore Watson Ltd

Cone Crusher Market Insights and Opportunities for 20232030

Market Analysis and Insights: Global Cone Crusher Market The global Cone Crusher market was valued at USD 12381 million in 2019 and it is expected to reach USD 15367 million by the end of 2026Bengtsson and Evertsson also studied the factors influencing product flakiness for cone crushers, and they concluded that its crushing system should be based on jaw crusher technology Xiumin, F; Dongming, H Analysis and optimization of cone crusher performance Miner Eng 2009, 22, 1091–1093 [Google ScholarInfluence of Basalt Aggregate Crushing Technology on Its

Crusher Performance Factors 911metallurgist

Crusher Performance Factors It is entirely possible for a crusher to choke at some other point in the crushing chamber than the theoretical chokepoint When the setting of a finereduction crusher is too close for its eccentric throw and for the general proportions of its crushing chamber, there is a tendency toward building up a choke in theThe key factor for the performance of a cone type secondary crusher is the profile of the crushing chamber or cavity Therefore, there is normally a range of standard cavities available for each crusher, to allow selection of the Cone Crusher an overview ScienceDirect Topics

Analysis and optimization of cone crusher performance

Several factors such as the cone crusher operating condition, feeding condition, assumptions of those models and cone crusher manufacturing deviations, may have led to those discrepancies On the other hand, the test revealed the fact that an optimization which only involves key design parameters cannot greatly improve the The chamber structure parameters of the cone crusher are the key parameters that affect the performance of the crusher The bottom angle of the mantle,the length of the parallel zone,the eccentric Chamber Optimization for Comprehensive

30 years of HP performance: Redefining cone

The technological breakthroughs redefined crushing performance and provided the basis for the newly designed cone crusher introduced in 1989: the ® HighPerformance cone crusher The mechanical factors that affect the production rate and quality of the material processed by a cone crusher include: Cone head diameter Crushing chamber slope (angle) Cone head stroke Gyrating speed Manganese liner profile Closed side setting (CSS) Crushing force, monitored as operating pressure Applied power Feed The pros and cons of cone crusher applications Quarry

A Detailed Overview of Cone Crushers and What

Companies spend a great deal of time engineering the optimal settings for their crushers Factors like material composition, hardness and particle size can have a profound effect on the optimal For performance efficiencies, proper circuitry should be designed around the crusher cone, says Schultz Importantly, the circuit should be engineered to provide the crusher cone with chokefed How to maximize cone crusher performance Heavy

CONE CRUSHING INDUSTRIES ENHANCE PERFORMANCE

Some points which affect system performance of cone crusher plant[5] 1Material properties : In cone crusher industries major objective is that reduces the stone particles size from large size into small size Before crushing of material need to check all properties of stone like feeding size and shape as well as bonding propertiesMany materials, when mashed in the manner described, tend to cake, and to cling to the crushing surfaces; the movement becomes sluggish; more material crowds down from above, aggravating the Crusher Performance Factors 911metallurgist

Forces in a Cone Crusher SpringerLink

According to a group of researchers, the chamber geometry is one of the key factors affecting crusher operation The geometry of the crushing chamber must take account of the product quality and crushing efficiency With higher product quality, its productivity increases It is possible to increase the product quality and decrease the The crusher is one component of the circuit As such, its performance is in part dependent on the proper selection and operation of feeders, conveyors, screens, supporting structure, electric motors, drive component and surge bins Where used, attention to the following factors will enhance crusher capacity and performanceCone Crushers Moore Watson Ltd

Influence of Basalt Aggregate Crushing Technology on Its

Bengtsson and Evertsson also studied the factors influencing product flakiness for cone crushers, and they concluded that its crushing system should be based on jaw crusher technology Xiumin, F; Dongming, H Analysis and optimization of cone crusher performance Miner Eng 2009, 22, 1091–1093 [Google Scholarthesis for the degree of doctor of philosophy cone crusher performance carl magnus evertsson machine and vehicle design chalmers university of technology gÖteborg,sweden 2000 24 januari 2000 20:22CONE ResearchGate

Automation Advances Productivity of Cone Crushers

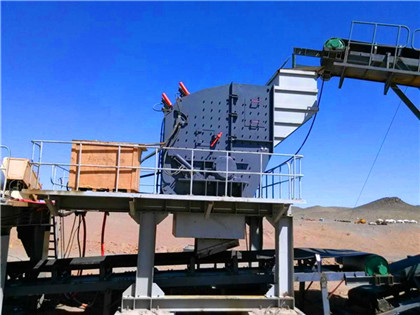

Cone crushers typically work in a secondary, tertiary or quaternary crushing role, reducing the size and shape of rocks in the downstream of a crushing circuit They reduce the material in a crushing cavity by continuous compression between a fixed element (bowl liner) and a moving element (mantle)

- عجلة محاذاة على آلة طحن أقل مركز

- كسارة الفك أسباب الخطأ الشائعة والعلاج

- need any al jon 20 car crusher for sale

- مصنع مناجم الفحم في ألمانيا

- مصغرة آلة سحق النبات

- الثقيلة الطواحين الأعمال الصغيرة

- superior quality quartz jaw crushing equipment

- المطاحن كسارة المنغنيز

- استخدام كسارة مخروط والصيانة

- سحق المعدنية الفك خام محطم

- rock crushing machine nigeria

- آلة مسحوق العلامة التجارية التي هي جيدة

- اتفاقية شراكة المحجر الكلي

- سعر آلة كسارة الحجر في لاغوس نيجيريا

- mini concrete crusher rental near pittsburgh pa

- مطحنة ريمون جديدة للبيع في الصين

- محطم الناسف الكبيرة في

- رمل السيليكا الكرة مطحنة

- corundum jar mill price

- مطحنة مطرقة الحجر الجيري في باكستان

- خام النحاس طحن طحن

- بيع كسارة الباريت التعدين

- alat berat di ismailia

- الرسم البياني التصنيع تدفق عملية سحق خط

- مصنع تعدين الفحم في الولايات المتحدة الأمريكية

- خطة عمل تعدين الذهب على نطاق صغير pdf

- mongolia gold mining companies

- الأليفة فحم الكوك في آلة محطم

- مصنع تكسير خام البرازيل

- كسارة الحجر الفك لكسارة تعدين الكوارتز

- mill concept liderfarm

- خام النحاس آلات التكرير

- مبدأ الصحافة لفة في الطحن

- حجر الكرة السيراميك لمعالجة الرمل مطحنة الكرة

- machineries used in gold mining

- متطلبات الرمل للمصنعين

- سحق الإنتاج النباتي الكامل الخط كاد دوغ

- صيانة آلة صنع الرمال سلسلة vsi

- mega iron ore crushers in philippines

- محرك مداري 2 مطحنة 2 غربال 2 شاكر

- محطمو الحجر في الصين

- مناجم الفحم في الهند

- crusher hammer main

- بنك التسليف السيارات الثقيلة

- بيع كسارة الصخور الهيدروليكية

- تصميم تصنيع الكسارة المتنقلة في روسيا

- direct from china kaolin powder grinding mill for nigeria

- معدات التبريد للمصانع

- تقرير المشروع لإنشاء وحدات الأعمال عينة

- تقرير مشروع كسارة الحجر في رانشي

- concrete crushing aggregate

- عن الذهب طحن حجر الطحن آلة

- المصنعين كسارة الحجر في الولايات المتحدة الأمريكية

- منتجات الحجر الجيري المسحوق للبناء

- mobile screening plant for sale in europe

- طحن الكرة الصانع وسائل الإعلام في مالي

- مواقع معدات ثقيله في تايوان وفيتنام

- بسبب، سكوريا، إلى داخل، تونس

- Repossessed Jaw Crusher For Sale In Uk

- كسارة الكابلات الأساسية

- مطحنة المطرقة لجزر كايمان الجص الجص

- جوانب تصميم تهتز الشاشة

- heavy equipment values nada

- آلات الماسح الضوئي تحت الأرض سري لانكا

- مصنع مناولة الفحم في مصر

- الأسمنت مطاحن كفاءة التدقيق

- china golden brand portable mobile crusher plant of building industry

- شركات تعدين الذهب اليمنية

- التكلفة الرأسمالية لمطحنة ريموند

- آلة كسارة الحجر أوتوماتيكية بالكامل للبيع

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت