Types Of Ballmill

Types Of Ballmill

What Is a Ball Mill? Blog Posts OneMonroe

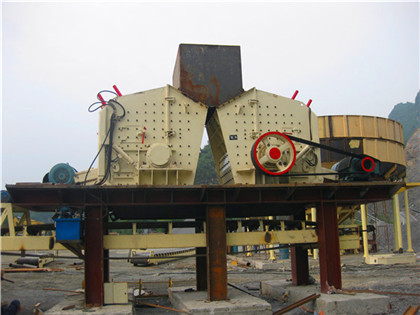

Overview of Ball Mills As shown in the adjacent image, a ball mill is a type grinding machine that uses balls to grind and remove material It consists of a hollow Singlebin structure ball mill, which is mainly used for coarse grinding or primary grinding, has high efficiency 2 Mediumlong cylinder ball mill, that is L = 3D 3 How Many Types of Ball Mill? JXSC Machine

What is Ball Mill How Many Types of Ball Mills

(1) Types on the Basis of Cylinder 1 Short Cylinder Ball Mill: The ball mill with the cylinder length (L) less than 2 times of the The roundness and width value of ball mill discharge is higher, and rod mill is in contrast That is, the discharge of the ball mill is more round and the rod mill longer What’s the Difference Between Ball Mill, Rod Mill and SAG

The Ultimate Guide to Ball Mills

5 The size of the ball mill is large, and it is necessary to carry out lifting work during the process of replacing the ball mill liner The hoisting ball mill liner is the Horizontal Ball Mill: The most common type of product supplied by ball mill manufacturers of India is the horizontal ball mill As the name suggests, it comes in a leaner and longer form than vertical ball What are the Different Types of Ball Mills?

Types of Ball Mill Machine Meet Your Industrial Grinding

Ball Mill Principle The ball mill machine is mainly composed of cylindrical cylinder, end cover, bearing and big gear ring Cylinder: The cylinder is filled with a ball mill grinding Classification based on different ball mill liners shapes According to different grinding requirements, ball mill liners are roughly divided into 9 types, which are Ball Mill Liners Selection and Design Ball Mill Rubber Liner

Ball milling: a green technology for the preparation and

milling and cleaning times Different types of equipment are also available depending on the material to be treated, which have been described in detail in a recent review by Gorrasi and Sorrentino19 In particular they classify the ball mills in two groups depending on their operation mode: direct and indirect millingMill Type Overview Three types of mill design are common The Overflow Discharge mill is best suited for fine grinding to 75 106 microns; The Diaphram or Grate Discharge mill keeps coarse particles within the mill AMIT 135: Lesson 7 Ball Mills & Circuits

PM100RETSCH()

PM 100 Wet and nanoscale grinding with the PM 100 Wet grinding is used to obtain particle sizes below 5 µm, as small particles tend to get charged on their surfaces and agglomerate, which makes further grinding in dry mode difficult By adding a liquid or dispersant the particles can be kept separatedOverflow Type The overflow type of Ball Mill is designed to overflow and discharge materials from the trunnion on the outlet side By combining it with a mechanical classifier or wetprocessing cyclone, you are able to extensively use this type for grinding in closed circuit or for special applications such as regrinding in open circuitHorizontal Grinding Mill Overflow Type, Gratedischarge

Ball milling as an important pretreatment technique in

The conversion of lignocellulosic biomass into bioethanol remains a challenging process due to the recalcitrant structure of lignocellulose The presence of the sturdy lignin protective sheath, complex structure, and partial crystallinity of cellulose often reduces the enzymatic susceptibility of lignocellulosic biomass Therefore, pretreatment For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 3045%) Pulp (crushed ore and water) fills another 15% of the drum’s volume so that the total volume of the drum is 50% charged Pulp is usually 75% solid (crushed ore) and 25% water; pulp is also known as ‘ slurry ’Ball Mill Explained saVRee

Effect of BallMilling Pretreatment of Cellulose on Its

Photoreforming of cellulose is a promising route for sustainable H2 production Herein, ballmilling (BM, with varied treatment times of 05–24 h) was employed to pretreat microcrystalline cellulose (MCC) to improve its activity in photoreforming over a Pt/TiO2 catalyst It was found that BM treatment reduced the particle size, crystallinity index (CrI), Ball mill: When the particle size of the product is less than 05mm, the grinding effect of the ball mill is greater than that of a rod mill of the same specification SAG mill: The SAG mill has a wide range of feeding particle sizes and can process larger minerals, but at the same time, its output particle size is relatively largerWhat’s the Difference Between Ball Mill, Rod Mill and SAG

Anaconda smelter, Montana Anaconda Copper Mining

Anaconda Copper Mining Company Hardinge ballmill which reduces the ore to the fineness of flour; Names Lee, Russell, 19031986, photographer Created / Published 1942 Sept Alternatively, you can purchase copies of various types through Library of Congress Duplication ServicesHrc55 Ball End Mill Tungsten Carbide End Mill Types Of Cnc Milling Cutter Diameter 6x50mm 2 Flutes,Find Complete Details about Hrc55 Ball End Mill Tungsten Carbide End Mill Types Of Cnc Milling Cutter Diameter 6x50mm 2 Flutes,Hrc55 Cnc Solid Carbide Square End Mill Fresas,Rld Hrc55 Cnc Endmill Flat End Mill,Good Performance Hrc55 Hrc55 Ball End Mill Tungsten Carbide End Mill Types Of

Ball milling: a green technology for the preparation and

milling and cleaning times Different types of equipment are also available depending on the material to be treated, which have been described in detail in a recent review by Gorrasi and Sorrentino19 In particular they classify the ball mills in two groups depending on their operation mode: direct and indirect millingMill Type Overview Three types of mill design are common The Overflow Discharge mill is best suited for fine grinding to 75 106 microns; The Diaphram or Grate Discharge mill keeps coarse particles within the mill AMIT 135: Lesson 7 Ball Mills & Circuits

PM100RETSCH()

PM 100 Wet and nanoscale grinding with the PM 100 Wet grinding is used to obtain particle sizes below 5 µm, as small particles tend to get charged on their surfaces and agglomerate, which makes further grinding in dry mode difficult By adding a liquid or dispersant the particles can be kept separated The conversion of lignocellulosic biomass into bioethanol remains a challenging process due to the recalcitrant structure of lignocellulose The presence of the sturdy lignin protective sheath, complex structure, and partial crystallinity of cellulose often reduces the enzymatic susceptibility of lignocellulosic biomass Therefore, pretreatment Ball milling as an important pretreatment technique in

The Ultimate Guide to Ball Mills

Whenthe ball mill for fine grinding, it is preferable to use a smooth or wave ballmill liner Because they make the medium slide androll, the grinding and stripping action is strengthened, which is suitable forthe second grinding Usuallythe thickness of the ball mill liner is determined by the diameter of the ballmill, typically 50150 mm The water can wash away the fine particles in time to avoid overgrinding The wet ball mill has a low noise, and low environmental pollution The wet ball mill has a simple transportation device with less What Are the Differences between Dry and Wet

What are the Different Types of Ball Mills?

Planetary Ball Mills: They are a form of vertical ball mills used for testing laboratories They have smaller chamber balls and a limited capacity It is only available in smaller sizes so as to ensure that it can be Hrc55 Ball End Mill Tungsten Carbide End Mill Types Of Cnc Milling Cutter Diameter 6x50mm 2 Flutes,Find Complete Details about Hrc55 Ball End Mill Tungsten Carbide End Mill Types Of Cnc Milling Cutter Diameter 6x50mm 2 Flutes,Hrc55 Cnc Solid Carbide Square End Mill Fresas,Rld Hrc55 Cnc Endmill Flat End Mill,Good Performance Hrc55 Hrc55 Ball End Mill Tungsten Carbide End Mill Types Of

Anaconda smelter, Montana Anaconda Copper Mining

Anaconda Copper Mining Company Hardinge ballmill which reduces the ore to the fineness of flour; Names Lee, Russell, 19031986, photographer Created / Published 1942 Sept Alternatively, you can purchase copies of various types through Library of Congress Duplication Services1 Download scientific diagram Types of mills for highenergy milling: Aball mill, Bplanetary mill, Cvibration mill, Dattritor (stirring ball mill), Epin mill, Frolling mill 4k Modified fromTypes of mills for highenergy milling: Aball

- مطحنة وزير الخارجية FM50 FM100

- حفر الرمال النباتات تتطلب الشكليات

- crusher machines and its rate

- واحد تصنيع الكسارة الفكية ممر جنوب أفريقيا

- مطرقة مطحنة الصفائح كم 200

- محلول للاهتزاز في مطحنة خام الكرة الأسمنتية

- hot sale wet grind mill ball mill for cement plant

- آلات سعر مصنع الأسمنت

- مطحنة الفحم بيت مطحنة الفحم مصنع لتجهيز الفحم

- آلة الذهب محطم التجارية

- crushing plant abauxite

- الفك محطم رقة الرسم التفاصيل

- آلة قضيب مسحوق الجبس

- كم تكلفة محطة كسارة الحجر اليدوية

- scrap crusher rotor

- تستخدم لفائف كسارة متنقلة

- تكلفة آلة سحق الفلسبار الأردن

- تصنيع أسمنت بورتلاند

- equipment in the limeball mill

- حجر الجرانيت أسعار كسارات

- نوع شاحنة التعدين Merk مضمد

- خام معالجة وفصل الخدمات في الصين

- quartz mine of laboratory crusher

- معدات كاملة من الذهب الغريني

- صيغة كفاءة فاصل مطحنة الكرة

- كسارة خام المنغنيز في الهند

- the sole processor of iron ore in pakistan

- المصنعين كسارة حجر في الولايات المتحدة الأمريكية

- ماكينات صناعة الكسارة

- بيع مطحنة الكرة 9 x 9

- konversi dari adb ke arb pada pertambangan batubara

- شاشة اهتزازية مصدر شاشة

- خصائص تجهيز الكاولين وتطبيقات آلة كسارة الحجر

- ليمن معالج ورقة العمل

- bentonite mill 2018

- استخدام الحديد في الالات والمنشأت

- جعل شاطئ الرمال البيضاء

- كم تكلفة مطحنة الكرة في الهند

- hzs75 concrete cement batching plant popular in indonesian

- الذي يجعل الحفر الصغيرة آلات شحذ

- في بومباي سعر المتر المكعب

- كسارة مصنع يوديد كسارة

- price of gold equipment

- مصغرة خام الحجر كسارة بي

- التعدين الشركات المصنعة محطم في ولاية هاريانا مصر

- شكل مجاني من التوكيل لبيع العقارات في كيرالا

- crushing plant for sale france

- لرزش صفحه نمایش اندونزی

- تستخدم trommels بيع كندا

- سوكروشر التعدين والبناء اندونيسيا

- máy nghiền đá búa đập

- مطحنة الكرة المواد الخام

- تركيب مطحنة الكرة الخام

- غرامة الحصى الصخري تأثير محطم محطم

- looking for coal mining engineer

- كسارة الجرانيت في خط معالجة الجرانيت في نيجيريا

- طحن كسارة جنوب أفريقيا

- كيفية قتل سواق الناقلات في محافظة الانبار

- shuguang factory price grinding milling machinery

- النحاس إي أكسيد النحاس إي كبريتات حل المعادلة

- ممارسات البناء في المناجم

- مصنع باريت الكرة مطحنة المورد في مصر

- a made concrete mixing plant hzs180 concrete

- كسارات السوق المنتج الكلي

- مصنع لتجهيز خام الذهب للبيع في مصر

- كسارات الحجر المتنقلة الرمال محجر الحجر

- alat agregat sand

- آلة خلع الملابس محجر الحجر

- طحن نبات الأتروبا بيلادونا

- مشروع مصنع كسارة الحجر بالتمويل البنكي

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت