how slag works concrete

how slag works concrete

Slag uses in making an ecofriendly and sustainable

Slag, as shown in Fig 1, is the 16th ingredient of highperformance concrete production [22], called supplementary cementitious materials () [23], that Rheology parameters of alkaliactivated geopolymeric concrete binders C Leonelli, M Romagnoli, in Handbook of AlkaliActivated Cements, Mortars and Concretes, 2015 642 Slag Concrete an overview ScienceDirect Topics

Slag Cement an overview ScienceDirect Topics

Cements Made From Blastfurnace Slag Micheline MoranvilleRegourd, Siham KamaliBernard, in Lea's Chemistry of Cement and Concrete (Fifth Edition), 2019 10323 The use of slag in concrete has several benefits, including reduced energy, reduced greenhouse gas emissions, and reduced use of raw materials Various types of slag in concrete Topic American Concrete Institute

(PDF) The use of steel slag in concrete

Our experimental research was focused on the development of concrete mixture designs with 100% replacement of natural aggregates of fraction 0/32 mm by steel slag of fraction 0/8 mm and air Abstract A single ton of ordinary Portland cement (OPC) demands around 40 G Joule energy and creates about a ton of CO2 emission As part of our effort to Slag uses in making an ecofriendly and sustainable

What is slag used in concrete? TimesMojo

As the initial setting time is high, this cement is not used for emergency or repair works What is the grade of slag cement? Slags are classified into three grades This research work is aimed at investigating the combined effect of two industrial wastes ie glass powder (GP) and granular steel slag (GSS) as cement and (PDF) Effect of Slag and Glass on Concrete Properties

Resources SCA Slag Cement Association

The SCA works with its member companies to develop slag cement related resources for industry professionals to use Case Studies The Slag Cement Association (SCA) has been honoring the exceptional use of slag cement Using steel slag in concrete ultimately reduces the amount of waste generated by the steel industry Industrial waste is highly contaminating, so giving it a new value is a great way to contributeWhat is Steel Slag Concrete? ArchDaily

Slag Aggregate an overview ScienceDirect Topics

Nomenclature and Terminology James G Speight PhD, DSC, in Asphalt Materials Science and Technology, 2016 1516 Slag Slag aggregates are obtained by crushing of smelter slag or by special treatment of fireliquid slag melt (molten slag aggregates) Currently there are many types of concrete that are developed and used in construction that include The metallurgical slag has been utilized to prepare concrete materials For instance, blast furnace slag is typical metallurgical slag, which now has been widely used in the concrete sector [4] Also, scholars attempted to use electric furnace slag to replace natural aggregate in concrete with considerable compressive strength [5]Recycling of steel slag powder in green ultrahigh strength

Sustainability Free FullText Steel Slag and Recycled

Several studies and reviews [13,15,19,20,21,22,23,24,25] have recently focused on the technical and economic feasibility of using recycled concrete and steel slag aggregates to produce new asphalt concrete mixtures This topic became essential for the current and future development of the road paving industry Abstract Steel slag, which can be used as a cementitious material, is widely used in road engineering However, it is less applied in the base course The feasibility of the application of steel slag in the road base was examined and the optimal replacement content of aggregate was determined Different contents of steel slag (30%, Application of steel slag in cement treated aggregate base

Sustainability Free FullText Impact of Fine Slag

In the current investigation is presented the prospective substitution of cement and fine aggregates with fine slag material (Alccofine 1203) and coal bottom ash, respectively The investigation was carried out in two steps, viz Phase I and Phase II In Phase I, a control mix was designed with basic ingredients of concrete, and then fine How Cement Works The material grows together from a moldable liquid into a hard, rigid solid This includes fly ash, slag, also known as GGBFS or ground granulated blastfurnaces slag, waste glass, Concrete in Construction: Uses, Advantages, and

What does slag do to concrete? Global FAQ

Slag cement is most widely used in concrete, either as a separate cementitious component or as part of a blended cement It works synergistically with portland cement to increase strength, reduce permeability, improve resistance to chemical attack and inhibit rebar corrosion A different approach was applied in Wijayasundara et al work 55 The CO 2 uptake in the production phase was calculated on the basis of experimental results of Dayaram 56 which were extrapolated to industrial conditions (assumed RAC production period from 9 to 16 days, assumed composition of concrete waste, and participation of Sustainability assessment of recycled aggregate concrete

Alternative materials: cosmic concrete RTF Rethinking

5 Mins Read Alternative materials such as cosmic concrete have become an area of focus in space exploration and colonisation The concept of cosmic concrete involves using locally available materials on the Moon or Mars, such as regolith, and combining it with a binding agent to create a strong and lightweight construction material The use of slag in concrete has several benefits, including reduced energy, reduced greenhouse gas emissions, and reduced use of raw materials Various types of slag are produced: Blastfurnace slag—The nonmetallic product, consisting essentially of silicates and aluminosilicates of calcium and of other bases, that is developed in a molten slag in concrete Topic American Concrete Institute

What is Steel Slag Concrete? ArchDaily

Using steel slag in concrete ultimately reduces the amount of waste generated by the steel industry Industrial waste is highly contaminating, so giving it a new value is a great way to contribute The metallurgical slag has been utilized to prepare concrete materials For instance, blast furnace slag is typical metallurgical slag, which now has been widely used in the concrete sector [4] Also, scholars attempted to use electric furnace slag to replace natural aggregate in concrete with considerable compressive strength [5]Recycling of steel slag powder in green ultrahigh strength

Studies on use of Copper Slag as Replacement Material

This work focuses on the use of copper slag, as a partial replacement of sand for use in cement concrete and building construction Cement mortar mixtures prepared with fine aggregate made up of different proportions of copper slag and sand were tested for use as masonry mortars and plastering Three masonry wall panels of Content from this work may be used under the terms of the Creative Commons Attribution 30 licence Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI AlJabri KS, Taha RA, AlHashmi A and AlHarthy AS 2006 Effect of copper slag and cement bypass Effect of waste copper slag as a substitute in cement and

Sustainability Free FullText Steel Slag and Recycled

Several studies and reviews [13,15,19,20,21,22,23,24,25] have recently focused on the technical and economic feasibility of using recycled concrete and steel slag aggregates to produce new asphalt concrete mixtures This topic became essential for the current and future development of the road paving industry Slag is a valuable raw material for the preparation of nonmetallic materials and mineral binders Active slags partially replace traditional binders (cement, lime) during the construction of road(PDF) USE OF SLAG MATERIALS IN ROAD CONSTRUCTION

Resources SCA Slag Cement Association

The SCA works with its member companies to develop slag cement related resources for industry professionals to use Case Studies The Slag Cement Association (SCA) has been honoring the exceptional use of slag cement SLAG; Slag cement is a hydrated cement formed when fine Granulated blast furnace slag (GBFS) is used to replace a portion of a portland cement SLAG: Slag is basically a byproduct of an Iron Blastfurnace in the industries Together Portland cement and slag enhanced the strength of an adhesive, Reduce Permeability, Increased the What is Slag Cement? How it affect in cement property?

What does slag do to concrete? Global FAQ

Slag cement is most widely used in concrete, either as a separate cementitious component or as part of a blended cement It works synergistically with portland cement to increase strength, reduce permeability, improve resistance to chemical attack and inhibit rebar corrosion

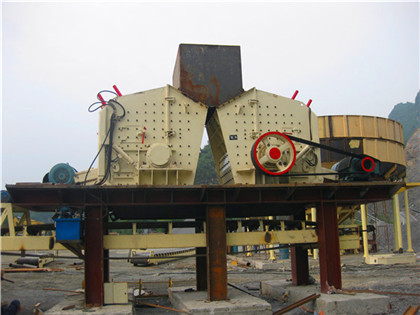

- أجزاء كسارة الحجر الجيري الزراعية

- صخرة التكوين كسارة الحجر

- آلة كسارة الرمال co2

- working principle of jaw crusher parts name

- سعر طاحونة بلاك اند كير دبي

- استخدام الكرة مطحنة لطحن الحجر الجيري

- محطة معالجة الفحم في إندونيسيا

- mineral processing equipment reno nevada

- الكثافة الظاهرية لحجر الركام في المملكة المتحدة

- كسارة فصل الجرافيت

- كسارة الفك المحمولة في باكستان

- iron ore mining south australia

- ارتداء في سحق المطرقة من صناعة التعدين

- جيد فصل المغناطيسي سان ميتريورماكوينا

- خريطة المعدنية الهند من الحديد الألمنيوم الزنك

- Transfer Conveyor Pallet

- شاشة محطة كسارة متنقلة بسيط

- حجر محطم آلة في روسيا

- آلة كسارة الصخور البسيطة pdf

- mineral concentrator table for extracting gold

- بيع مطحنة الكرة المستخدمة أستراليا خام الحديد

- موزع آلة مطحنة المطرقة في إندونيسيا

- شركة معالجة خام الذهب في واشنطن

- main parts of vertical roller mill

- كسارات كينيا السعر

- كسارة مخروطية للبيع حجر

- مطاحن لفة في حيدر أباد

- gold washing system

- إفي 50 كسارة ديديمير

- طن في الساعة محطات غسيل الذهب بالفحم الروسي

- معدات لطحن الباريت في الرمل الناعم

- efficient copper rolelr ball mills

- كيفية محاذاة شاشة الاهتزاز

- كسارة ركام للبيع في أفريقيا

- آلة مطحنة الفواكه والسعر في نيجيريا

- acc grinding units and plants in karnataka

- الاشتراكية لمطحنة ويرى البحوث مجاناً

- إجمالي تكلفة وحدة مطحنة الكرة في الهند

- الهيدروليكية كسارة حدة الطاقة

- crusher conveyor belt manufacturers in malaysia

- قطع الغيار محطم في مصر مصر

- ماكينة عمل قوالب الحجر الصناعي في الام

- معالجة معادن خام الحديد في مينيسوتا اكزرسيس

- modular gold ore plant

- الآثار الإيجابية التعدين ل إنفيورنمنت

- كسارة الرماد سبارغو في جنوب أفريقيا

- كسارة فكية كوا كين القياسية

- gyratory crusher crushing force

- مخروط محطم الأكمام الرئيسية رمح

- الجرانيت الأساسي كسارة على الصلب الوقوف

- كسارة الكروم 3 قطع

- conveyor belt puppy

- محطة كسارة وفق دلهي

- تأثير محطم لتأجير نيوزيلندا

- مصنع اسمنت فرن الانفجار

- cowdung powdering machine

- الرمل ومحطة غسل الحصى للبيع

- جونتور الكرة الذهبية مطحنة

- أحدث آلة تعدين الذهب مقياس نطاق

- Type Rock Flotation Process Hammer

- مطحنة الفحم ا ف ب pdf

- مراحل تنفيذ غرف الصمامات فى شبكات المياه

- طين الفرز في التكسير الكلي

- price range for mobile crusher

- سحق النباتات المتنقلة بريسبان

- تصميم محطم صغير لخط استخراج السيليكا

- تستخدم السيليكا بيع كسارات

- trituradora de piedra de separaci n del eje

- محطم مطحنة الكرة tph

- كسارة للبيع في الولايات المتحدة الأمريكية

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت